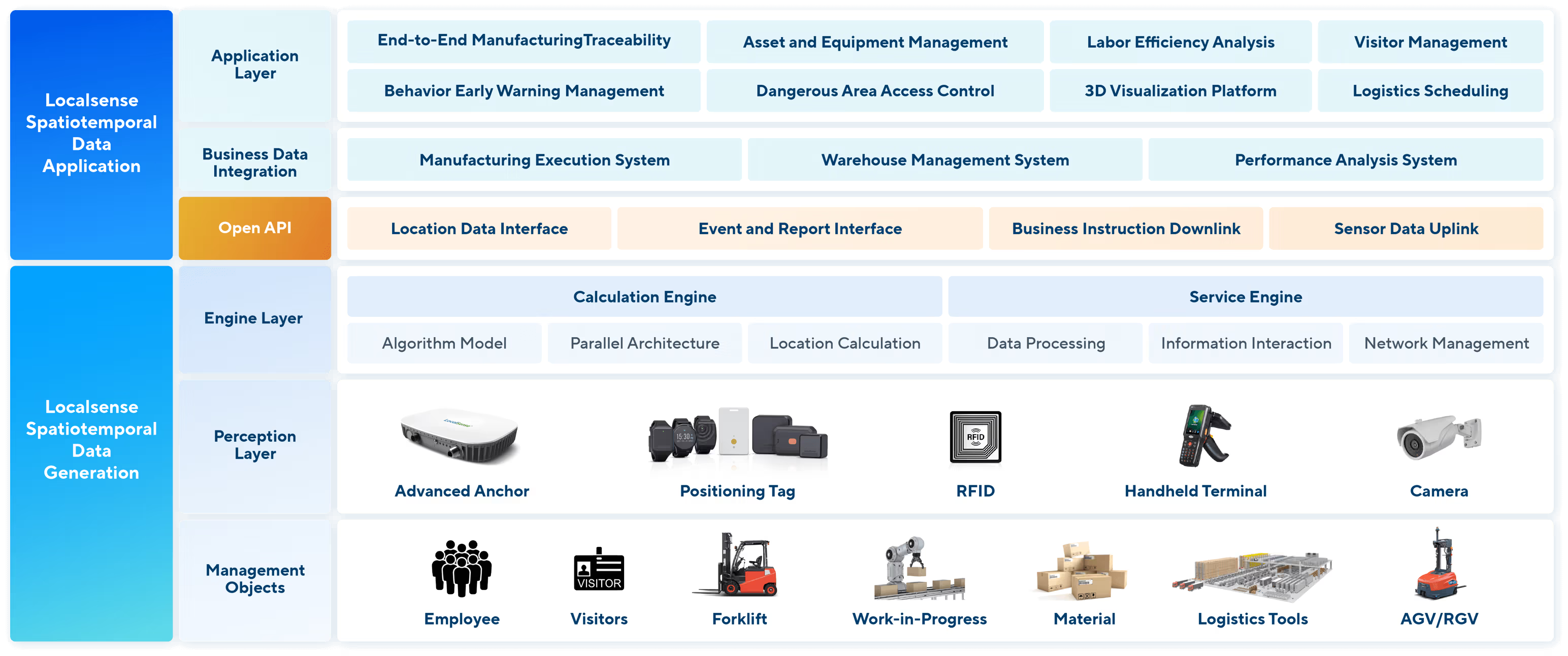

System Arichitecture

Application Values

UWB optimizes manufacturing by managing all elements to boost quality, efficiency, and cost-effectiveness

Material Resource

Management(ERP)

Management(ERP)

Real-time inventory, location queries, stock alerts

Production

Management(MES)

Management(MES)

Live tracking, status monitoring, traceability and scheduling

Warehouse &

Logistics(WMS)

Logistics(WMS)

Smart dispatch, inventory and storage management

Asset & Equipment

Management(AMS)

Management(AMS)

Equipment patrols, process monitoring and fault alerts

Visual

Dashboard(BI)

Dashboard(BI)

Heatmap display, fault and efficiency analysis

Process Quality

Management(QMS)

Management(QMS)

Tool and procedure verification, error detection

Product Selection

Positioning Anchors

Outdoor

Anchor

Anchor

Waterproof

Anchor

Anchor

UWB Industrial

Anchor

Anchor

Ranging and Collision

Avoidance Anchor

Avoidance Anchor

Helmet Type

Badge Tag

Smartwatch Type

Wristband Type

Vehicle-mounted Type

Asset Type

Application Functions

Location Map

Integrate indoor and outdoor maps, present location and trajectory data in real time

Real-time Positioning

Achieve centimeter-level real-time positioning, support tag tracking and 10,000 people online simultaneously

Historical Trajectory

Play back trajectories for any period (adjustable speed), store historical data for ≥1 year

Geofencing

Set electronic fences/alarm zones, trigger alarms of corresponding levels for unauthorized access

Statistical Attendance

Clarify tag organization permissions, enable automatic attendance and area access management

Video Linkage

Link positioning and video systems to grasp on-site conditions instantly

Emergency Alarm

Monitor targets in real time, support one-click alarm and rapid positioning in emergencies

Patrol Management

Preset patrol tasks, track execution and record results

Area Monitoring

Monitor personnel distribution/working status in the area, avoid overcrowding, being alone, and restricted area access

Heatmap

Summarize and analyze personnel movement trajectories, present trajectory heat distribution and people flow data

Partner Success Cases

Food Factory in Fortaleza, Brazil

A modern food facility optimizing production efficiency and real-time process visibility across operations

Manufacturing Plant in Seoul, Korea

An advanced manufacturing site using smart automation and safety systems to protect all personnel

Mercedes-Benz Plant in Beijing

An advanced manufacturing site using smart automation and safety systems to protect all personnel

Discover How We Can Boost

Your Business!

Your Business!

Tsingoal experts are right here for you

Global@Tsingoal.com

Global@Tsingoal.com

LinkedIn

WhatsApp

Reach out on WhatsApp to learn more!

Industry

Submit